Sales Manager of Cherbros Mr Helias Kakionis made an interview to the “Thermohydraulic” magazine. In that interview he refers to the Stratetic course the company followed during the economic crisis. A strategic that provided a dynamic course in and abroad Greece increasing their export incomes by 22% of their annual turnover

Interview with Elias Drallo

The strengthening of the company “CHERBROS / K. Cherubheim Bros. SA” through an investment program of 3.3 million euros and its export orientation significantly improved its position in the Greek market and made its brand name recognizable in foreign countries.

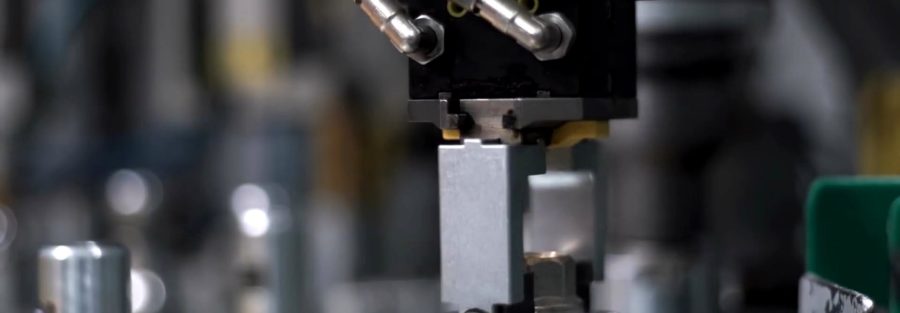

Mr. Elias Kakionis talks to us about the communication design, the upgrade of the production with the purchase of mechanical equipment of modern technology, the acquisition of building infrastructure, the assurance of the quality of the products, the importance that the company gave to the training of its human resources and mainly for the registration of its trademarks on the global platform of the WIPO organization.

He does not hide that the above successes do not cause complacency in the management of the company, but on the contrary they give impetus to further search for better products and to strengthen its collaborations. It is indicative that recently presented the new series of ball switch and cannula DIVA, a product “made in Greece”.

He believes that competition can help you become productive and thinks that Greek producers working to market a branded and certified product are partly allies and not just competitors, because they build the Greek brand name.

Finally, he reveals that his company has also fallen victim to scams that copied its products and was forced to take legal action, while noting that the best investment for the company is its human resources and customers.

More specifically, the interview is as follows:

– Mr. Kakioni, the company “CHERBROS / K. Cherouveim Bros. SA” is active in the design, production and marketing of brass parts for water supply, heating and solar systems, having achieved a remarkable growth in the Greek and foreign markets. What do you think is the key element that made you a strong player in the industry?

– CHERBROS has its roots in the late 1940s, when the Cherubim family began to be active in the manufacture of brass parts.

The experience and passion of all these years were passed on to the next generations of the family, who are now in control.

With a stable policy, CHERBROS continues to design and produce – based on European standards – high quality brass parts.

Experience and technology are our key elements. Our human resources and collaborations with leading companies / customers who believed in our vision are the elements that strengthened the recipe that sets us apart.

-Over the last decade the company made a series of business choices that further strengthened its position and made the corporate brand “CHERBROS” recognizable in the domestic and international market. What were these choices?

-In such a unstable economic environment as in recent years in Greece in the last decade, the decision taken by the management, and in particular the general manager Mr. Stamatis Cherouveim, was to be alerted and follow the needs of the market and the evolution of technology. For us, the risk of moving forward was a one-way street.

So the management of CHERBROS, focused on the development and not on the problems of the crisis, since 2009 started an investment program which has exceeded the amount of 3,300,000 euros in a decade. The largest part (approximately 2,600,000 euros) was invested in the purchase of modern technology mechanical equipment. The amount of approximately 700,000 euros was invested in building infrastructure.

With these investments, our production was standardized and the production line became more functional. The quality control department was reinforced with new technology measuring tools, such as hardness meter, spectrometer, etc.

We supported the human resources with training, while at the same time our communication with the companies / customers became stronger and we shared the same appetite to highlight a reliable Greek product.

During the same period, we participated in over 20 local and international exhibitions throughout Europe, in order to make our production known to the world. At the same time, we have registered two of our corporate brands on the global platform of WIPO.

All this effort was made to highlight our product itself that bears the embossed or printed logo “CHER”.

– Tell us in which countries do you export and what is the response of the international markets to Greek products, when at the same time you have to compete with strong foreign competitors?

– Our exports are to the countries of Europe, the Balkans and the Middle East.

Our effort to expand in foreign markets started systematically in 2010.

We made a round of exhibitions and business contacts in Europe and the Middle East, gathered information from chambers and consulates and traveled to understand the differences of each market.

The main problem we faced was the lack of a Greek brand name which we had to replace.

At the moment our exports are at 22% of our annual turnover. Of course, the competition is great and has many profiles. It is very large in volume and number, either with a stronger brand name or cheaper with questionable quality. Our effort to highlight the Greek brass component continues with the same intensity.

– Describe to us the product categories you produce and market and list the advantages you offer.

– In our shopping directory you will find:

* Switching material such as ball valves and taps, mini and angle valves, radiator valves, rotary valves.

* Mechanical clamping fittings for copper pipe systems, polyethylene pipe and multilayer pipe, as well as fittings for solar installation systems.

* Heating components and underfloor systems.

* Accessories screwed and glued.

All components are designed and manufactured in accordance with the standards required by European legislation. The raw material is the brass alloys CW617N and CW614N, as defined by the EU, suitable for the production of components for drinking water systems. Depending on each species produced, we have carried out the corresponding laboratory tests.

The auxiliary components that we use in the spherical valves are certified for drinking water, while the internal opening / closing ball has a certified TEA coating cover. against salts.

The company has certification of its production process according to ISO: 9001 and is aware of environmental issues, therefore has entered into partnerships with recycling companies (waste, packaging, etc.).

Do you plan to expand your product range in the near future and enter into strategic partnerships, either in terms of marketing or production?

– Recently we introduced our new series of ball valve and cannula “Diva”. We are very proud of the product design and the choice of auxiliary materials we chose to use. It is a high quality product, suitable for drinking water, and our first product where we write “made in Hellas”.

The management of a production unit, however, never stops envisioning and testing new products. He constantly thinks, plans and testing. The market rules are our only restrictions. They will give us the moment we will present our next product.

We consider our valuable partners and allies to be our client companies and their human resources, who have believed in us and our goal.

They are the ones who will tell us their point of view and we will share our ideas with them. They are the right ambassadors for our products, and we thank them for that.

– What is the vision and strategic plan of your company, in order to remain in a leading position? Are you thinking of changing your business model and expanding into other areas of the water, heating and solar installations?

– We have used the thread of a component as an element on our logo. A thread is the point that unites us with something else. Also with the spiral we symbolize the movement that never stops. It is the constant search to unite with the next idea and the next interpersonal relationship. It is this search that makes us think about the next, the best move.

At the same time we have the constant of quality and truth of the product that you can not hide. These we follow and with these partners we go.

– What do you consider to be the new market challenges, given the evolution of technology and the application of new rules and specifications in the services provided?

– The new elements in our market are automation and e-communications. With the frantic pace of everyday life, there is a need for individuals and professionals to have control over various building systems, to avoid an accident and of course for immediate intervention. It is also a new area for us with many challenges, and we are working on it. We are still in the early stages.

– What is your opinion about the competition?

– Competition is part of the market. Fair or unfair, the competition is the same. The moments when you were in a weak position, the competition overcame you. At that moment, the competition can be productive for you. It puts you on alert, to recognize the mistakes you made and to see how you can overcome the difficult situation you are in.

An important point of the competition that we have mentioned earlier is the brand name. It acts as a security element and influences the decision of the consumer in his final purchase.

I would like to refer to the Greek producers who work with the aim of placing on the market a branded and certified product. We consider them to be partly our allies and not just competitors. Their effort is to support the high quality Greek component and it is the one that builds the Greek brand name at the same time.

– In the market there is a lot of talk about the illegal materials and components that are being distributed uncontrollably in the water supply and heating sector, without certification, while it is not excluded that they are copies of genuine components, but do not meet the construction and safety standards. Have you encountered similar incidents? What measures do you think should be taken for this phenomenon?

– Each market contains all the elements you mention. There are good and bad times in the market. Copies and poor quality products are bad times. We happened to find copies of our own parts, several years ago, and we proceeded with a seizure process.

It’s something that happens, and there are not many ways to prevent it. CHERBROS has registered its trademarks with the global body WIPO, as a protection measure.

– What is the culture that governs the management and human resources of your company?

– In recent years, CHERBROS, despite the particularly difficult circumstances prevailing in the market, has invested in machinery and building infrastructure.

The management considers that the main investment is the human resources of our company and our customers. They are the ones who believe in the quality of relationships and advocate the quality of CHERBROS.